Mastercam 2025 Full Download Crack With Emulator (Dongle Patched) | 2025

Download the Mastercam 2025 Full Download Crack With Emulator (Dongle Patched) | 2025 from this link…

Summary

When I first started using Mastercam, I didn’t fully understand how much it would change the way I approached milling and machining tasks. Over time, I’ve seen the software evolve with true advancements some of which felt absolutely revolutionary. One of the most impressive additions is the Deburr tool. It’s made finishing work so much faster and cleaner, especially when combined with High-Speed Finishing Passes. Whether I’m working with Thread Milling operations or optimizing toolpaths, the system’s ability to adapt and provide powerful functions continues to impress. The Y-Axis Turning Support is another big win, and for those using Y/A/B Axis Turning setups, the improvements are easy to notice.

Across different shops I’ve worked with, from local facilities to teams worldwide, the feedback has been consistently positive. People appreciate how intuitive the interface has become it doesn’t feel overwhelming anymore, which helps new users settle in quickly. The Analyze Deviation Function stands out during complex part verification, helping to catch errors early without increasing production time or costs. These enhancements aren’t just minor tweaks; they represent thoughtful changes based on real-world use. As someone who relies on efficiency and reliability, Mastercam delivers where it counts, making a direct impact on performance every single day.

Mastercam’s Toolpath Flexibility for Multi-Axis Turning

As someone who has spent years working with CNC Machines, I can confidently say that Mastercam truly shines when it comes to Multi-Axis Toolpaths. During my training sessions, especially while working on 4-axis and 5-axis setups, I found the Toolpaths in it incredibly flexible. The program runs smoothly whether you’re using Haas machines or other CNC Milling Machines. With 13 lessons included in the Instructional Training Guide, the content builds gradually, making even turning operations with Y/A Axis Turning feel intuitive.

Organized Learning with Practical Tools

When creating NC code using Multi-Axis CNC Milling Machines, I appreciated how the software included options to create and simulate the code before sending it to the machine. The book format even came punched and ready for a binder, which made organizing the instructions super convenient during my early training sessions. These exercises are practical and help reinforce complex axis maneuvers and machining strategies.

Fine-Tuning with Threading and Feed Adjustments

In terms of performance, it delivers unmatched speed and precision, especially during programming tasks for deep thread cutting or complex toolpaths. The integration of feed controls and feed rate customization ensures accurate finishes. Each lesson in the guide dives deep into these topics, enhancing your ability to handle detailed programming needs across various types of machines.

Complete Learning Experience for Long-Term Mastery

Whether you’re learning through the Home Learning Edition Software or hands-on instruction, it equips you with the tools to succeed. From the installation process to handling popular machine types like Haas machines, every element is included to guide you. I’ve used the download version of the software and had 1 year of access to all essential training materials. It’s not just another CAD/CAM tool; it’s a full learning and product experience focused on practical applications and long-term skill-building.

A New Edge in Deburring

Working with it has always made my work smoother, especially when it comes to removing sharp edges. The Deburr feature saves time with its automatic approach and intuitive controls. I remember struggling with manual deburring, but now the process flows efficiently, using edge detection to guide the deburring paths accurately.

Rotational Turning Made Smarter

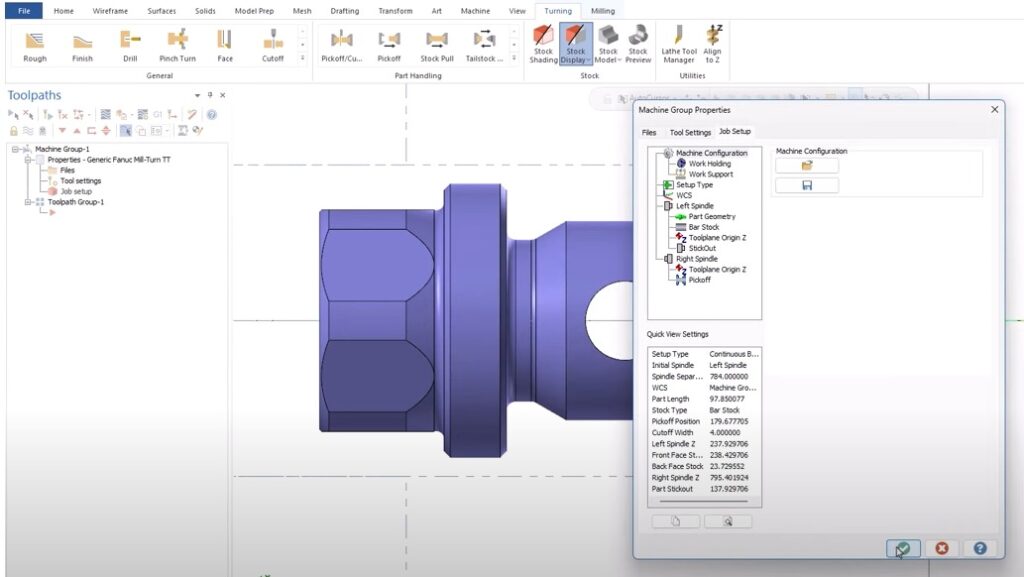

What impressed me most recently is Mastercam Mill-Turn’s upgrade with Y/A-Axis Turning. The addition of A-axis and B-axis contour turning complements existing toolpaths. Since Mastercam 2023, this new functionality has really extended the software’s support for rotary and custom thread operations. It’s a clear sign of how turning strategies are evolving to match complex needs.

Refining Threads with Smart Control

I was testing the new Thread Mill Enhancements in Mastercam 2025 just last week. What stood out was the Speed/Feed Override, allowing me to fine-tune the feed rate and Tool edge behavior. The gradual lead-in/out strategy adds smoother transitions, especially during lead-in/out adjustments, which reduce wear and boost tool life.

Listening and Evolving Through Feedback

As Meghan West, President and CEO, shared, it evolves by listening to its users. My own experience aligns with this. The customer experience feels tailored, with features developed through real feedback. Whether it’s for job setup or job completion, the software focuses on automation, efficiency, and productivity, staying responsive to the changing needs of the manufacturing community.

Breaking Limits in Multiaxis

When I moved into multiaxis operations, it’s Expanded Multiaxis Pocketing and 3+2 Automatic Roughing stood out. These new techniques are incredibly efficient for single-setup roughing and finishing. With flowline cutting, UV direction control, and tool contact management, I could optimize every cut on the surface models, which helped save time and stock. The milling feels smarter, more streamlined, and faster than ever.

Smarter Turning Applications

Another strong point is the wide support for turn-related applications. From modeling chuck jaws to using collet chucks, Mastercam Simulator gave me a realistic preview. With Mastercam Mill and Mastercam Lathe working together, especially on Swiss machining, it’s easier to deal with specialized post processors and ensure accurate G-code. It even supports machine-specific controls, improving the range of machines that can be directly supported.

Safer and Faster NC Programming

In my latest project, I made full use of the NC Programming tools. The Advanced Drill helped create customizable drill cycles for deep hole drilling, spot drilling, and back spot facing. The new Chamfer Drill uses the tip angle to handle holes of various sizes, diameters, and planes, machining all in a single operation. The Wrap option reduced the bounding box size, and with Check Tool Reach, I could view tool limits in the model geometry boosting both speed and safety.

System Requirements and Installation Simplicity

What makes it stand out is its ability to handle updates and installations directly on a 64-bit operating system. This support is not available for 32-bit OS, so make sure your system matches the software’s requirements. The installation is seamless, especially if your maintenance expiration is after March 31, 2025. I’ve worked on multiple machines, and each time the automatic update process saved me hours of setup time. The online access feature with username and password makes it easy to retrieve the instructional videos or video instructions wherever I am.

If you want to Purchase KeyGen Activator / Cracked Version /License Key

Contact Us on our Telegram ID :

Join Us For Update Telegram Group :

Join Us For Updated WhatsApp group:

Crack Software Policies & Rules:

You Can test through AnyDesk before Buying,

And When You Are Satisfied, Then Buy It.

Lifetime Activation, Unlimited PCs/Users.