CNC Simulator 3.1 (Master CNC Digitally) Download

Download the CNC Simulator 3.1 (Master CNC Digitally from this link…

Summary

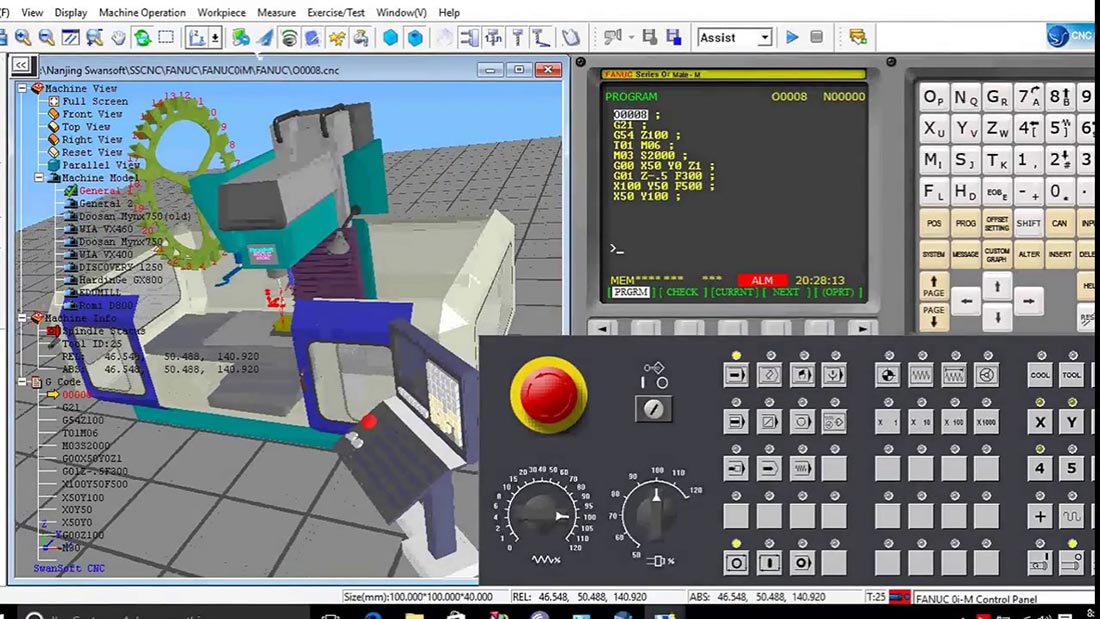

CNC Simulator, When I first stepped into my small workshop as a curious hobbyist, I never imagined how much time and money I could save by using a Windows application like CNC Simulator Pro. Instead of risking an actual machine, I began to simulate various CNC programs on my computer, testing and improving every line of code. It was a game-changer. From milling machines to turning machines, even plasma cutters and laser cutters, I was able to optimize each virtual run with precision. The efficiency and effectiveness of this tool brought real value. I didn’t need to worry about damaging expensive parts or putting operators at risk; it simply gave me the freedom to develop and experiment safely.

I found the CNC programming journey incredibly rewarding, especially with the support of computer-aided tools. Whether I wanted to explore water jet cutters, 3D printers, or even plotters, this ideal tool offered full simulation for 2-4 axis machines. Over time, I improved my CNC skills, which made teaching others in my local school smoother and more interactive. Watching students learn through testing and simulation, just as I had proven the long-term power of digital-first programming. By using this method, we not only preserved resources but also ensured safety while fostering true learning and curiosity.

Precision and Possibilities in Simulation

Working with CNC Simulator Pro has shown me just how far simulation technology has come in recent years. As someone teaching CNC at a school, I needed a solution that brought performance, accuracy, and flexibility into one platform. This software transformed our CNC classrooms by enabling trainees to interact with a Full 3D CNC Machine Simulator right on a PC. With Windows 10 or later, an Internet connection, and at least 4 GB of RAM, even a standard Intel Pentium system handles it well. The built-in Turbo Simulator allows simulation speed to be tested and optimized for smooth transitions between real and virtual processes.

The Value of Smart Programming Tools

What I find truly exceptional is the customized CNC editor with color highlights, code explanations, and quick suggestions. This enhances the CNC programming experience and simplifies debugging. From blockscript editor tools to MACRO programming and customized G-code interpreters, the system supports many CNC code dialects, including Fanuc and Heidenhain conversational language. You can build macros in the MACRO language and control machine behavior using the block script commands. Even command structures like M00, M01, T0 tool, and F and S values are editable, making the system truly programmable.

Feature-Rich for All Needs

The CNC Simulator offers everything from DXF Import/DXF Export, Image Maker, SimCam, and engraving functions, to analyzing G76 parameters, U and W direction, and rough cut cycles. You can simulate Z movement, switch between lathe and mill, test SimCam contour, and even create a guide circle or guide line. For each insert command, the system checks for absolute centers, verifies arcs, and uses arc check and new arc check methods to validate paths even down to .5 mm radius.

Designed for Education and Industry

For training institutes and instructors, the wide range of interactive exercises, Video tutorials, and e-learning classes makes the software ideal. The Training Friendly structure is built to enhance learning through examples, tutorials, and applied CNC concepts. As someone who started as a trainee, the clarity of start pos, start point and detailed help labels really accelerated my progress.

Expandability and Integration

I’ve also explored how well it connects with external systems. Jog controller support, DIY Arduino projects, and file handling through .cnc files, user CNC files, and Import DXF functions all work seamlessly. You can also access the system’s object library, store items in cloud-based storage, and simulate aspects like Simulate weight of workpieces or switch between machine types like 3D printers, hobby machines, routers, and more.

Error Handling and Stability

One highlight is the system’s resilience in managing errors like firewall blocks or memory error messages. The developers fixed bugs related to decimal commas, absolute center, postprocessing, decimal format, and even tricky cases like latency in simcam output or formatting in mill PP. The help desk, backed by a robust ticket system, ensures you’re never stuck for long.

Visual and Functional Control

With tools like the SimCam menu, SimCam settings, and SimCam dimension settings, control is both visual and functional. Features like pop-up intellisense, frame maker, frame guide, and editable editor make complex operations manageable. The system adapts to resizable window options and respects modern UI expectations.

Built for Scalability

Even as your needs grow, the system scales with you. The software suite is full of professional-grade options, from advanced CNC programming and Milling software to customizable code, Insert command, and support issues resolution. You can even use the translate function and translate CNC code to move between environments or languages.

Compatibility and Standardization

Built on the ISO standard, the software is both robust and compatible, easily syncing with industry standards. Whether it’s command fix, formatting G-code, managing Z origin, or using $-commands, the structure remains consistent. Special features like tool reg, tool changes, cutting, and arc tangenting maintain uniformity.

Final Thoughts from Practical Use

From the moment I tested it on a modern computer with the .NET Framework 4.8, I knew this wasn’t just a training aid. It’s a fully integrated CAD/CAM environment with CAD/CAM capabilities that supports everything from gear creator and gear maker to custom setups. The interface balances powerful features with a user-friendly approach, making it perfect for both education and real-world production.

If you want to Purchase KeyGen Activator / Cracked Version /License Key

Contact Us on our Telegram ID :

Join Us For Update Telegram Group :

Join Us For Updated WhatsApp group:

Crack Software Policies & Rules:

You Can test through AnyDesk before Buying,

And When You Are Satisfied, Then Buy It.

Lifetime Activation, Unlimited PCs/Users.